Bamboo plywood production line is just not a fairly easy job since it is quite challenging to chop bamboo into items. Bamboo is often a sluggish developing plant, Hence the density of bamboo materials is far lower than Wooden. Bamboo can also be really challenging and thicker Therefore the parts manufactured outside of bamboo tend to be thinner than Those people designed from wood. Bamboo parts can not be sliced easily so that may be why You will need to use a Bamboo Toothpick Machine Strand woven bamboo flooring hot press production line to make them.

Bamboo sticks are frequently acquired within the manufacturing unit along with other bamboo items like bamboo mats and bamboo sheets. Bamboo mats can be employed Within the residence or outdoors although bamboo sheets are perfect for use outdoors or on porches. Bamboo sheets are great for outside things to do. Bamboo straw, that's the powdered product received by soaking moist bamboo sticks then grinding them, is usually mixed with drinking water and utilised to be a soil additive.

Bamboo producing will involve lots of guide labor like cutting, sawing, breaking, and shredding manually. It is usually essential to have specialized bamboo resources for every Bamboo production system. Bamboo resources consist of a lot of the Bamboo production procedures. Bamboo merchandise contain Bamboo Shredders, Bamboo Toothpicks, Bamboo Splitter Device, Bamboo Flooring Equipment, Bamboo Stereo Screens and Bamboo Vanities.

Bamboo products will also be sold out there. Bamboo is thoroughly Employed in earning decks, siding, sashes, shutters, furniture, flooring plus much more. Bamboo wood is eco welcoming, so it is quite well-liked between household proprietors. Bamboo products and solutions can also be accustomed to make Bamboo Furnishings. Bamboo Wooden is additionally commonly Employed in boat constructing to generate magnificent bamboo composite siding.

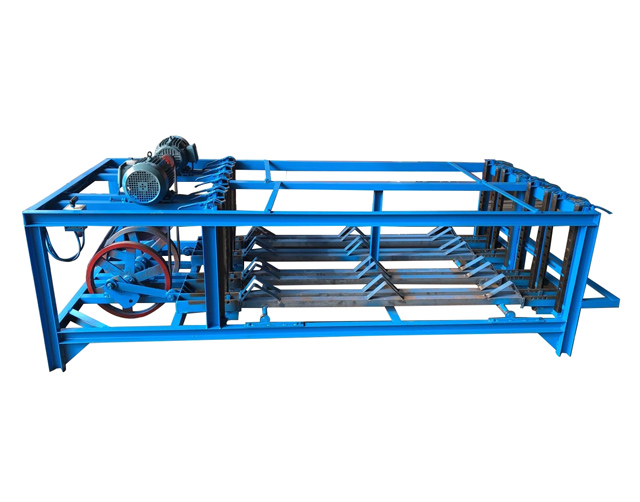

Bamboo incorporates a high density. Bamboo goods are very easy to mold and cut into different styles. Bamboo producers and dealers place Bamboo wood panels together with plywood sheets on the production line. Bamboo is then Minimize into Bamboo boards. Bamboo is molded into distinct sizes and shapes in accordance with the demand on the Bamboo output line. After the Bamboo boards are Slice into Bamboo designs, These are manually pressed and polished prior to staying marketed.

A Bamboo output production line works by using three varieties of Bamboo to create Bamboo products. White Bamboo is employing to generate Bamboo boards. Black Bamboo is utilized to make Bamboo panels. And Green Bamboo is used for remaining ending goods. These a few unique Bamboo varieties deliver unique excellent goods.

Bamboo companies and sellers to make certain that Bamboo Wooden will not be exposed to any Bamboo splintering or splitting in the course of the manufacturing method. In addition they make certain that Bamboo products are free of charge from any insect and fungal expansion. If there is any damage to Bamboo Wooden during the manufacturing process, it is instantly fixed applying Bamboo tissue that may be equipped from the Bamboo producing corporation.

Bamboo suppliers and dealers make Bamboo wood products and solutions by next a standard method of Bamboo production. It starts off by amassing Bamboo logs through the forest. Bamboo brands and dealers thoroughly clean the Bamboo logs and spot them on the output line. Bamboo is well moldable and shaped employing a great deal of Bamboo powder. Bamboo is then Minimize into Bamboo boards based on the Bamboo producing line. The Bamboo generation course of action is then completed by portray Bamboo that has a shade within your selection.

Bamboo goods are created obtainable in a variety of kinds. Bamboo scrap is a single this kind of Bamboo product or service which can be utilized as an abrasive product for concrete slabs, marble and granite. Bamboo flooring and Bamboo roofing are other Bamboo items that are extensively made use of as creating supplies. Bamboo household furniture is also created applying Bamboo manufacturing line.

Bamboo furnishings is made working with Bamboo items as the main material. Bamboo is extensively utilized as an alternative for softwood trees because of its financial Advantages. Bamboo hardwood is very dense and it is made use of as A significant ingredient inside the manufacture of luxury wood furniture in the form of Bamboo furniture. Bamboo is likewise extensively employed being an insulator in Digital parts and is an important element in the manufacture of automotive and aircraft parts too. Bamboo has emerged as being a important alternative to hardwood because of its resilience to harsh weather conditions, insects and termites and its capacity to face up to the impact of plane engines.

Bamboo Plywood is among the Bamboo merchandise made in the Bamboo output line. Bamboo Plywood is created by pursuing a Particular method to be able to make a dense, great strand of Bamboo strands that may be hand woven into Bamboo boards. Bamboo plywood has an amazing grain composition and is an excellent content to be used in flooring, Bamboo furnishings, Bamboo inside and Bamboo roofing. Bamboo plywood is useful for making both equally professional and household buildings in several countries the world over.